0086-18861028088

Rotary Drum Filter is widely used in various industries such as fine chemicals, pharmaceuticals, and food. Its fully enclosed design and high-efficiency filtration capability make it an indispensable piece of equipment for continuous production.

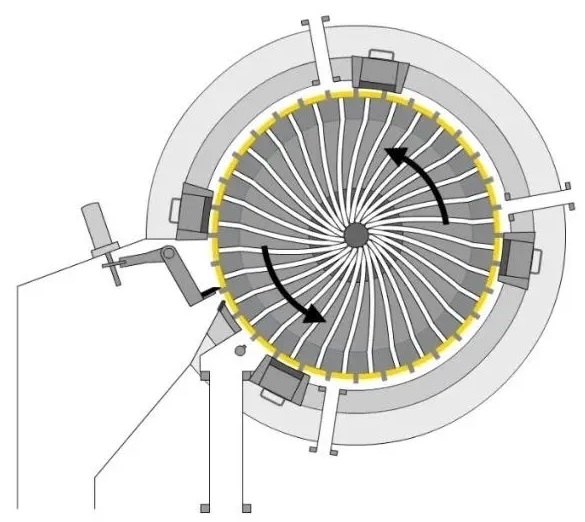

Rotary Drum Filter's core construction includes the housing, drum, compartments, control head, and drive system

Housing and Compartments

The housing is divided into multiple sections by the compartments, each equipped with different functional inlets and outlets according to process requirements, such as slurry inlets and washing medium inlets. The compartmentalization allows the drum to operate independently in different working sections, meeting complex production requirements.

Drum and Filtration Elements

The surface of the drum is divided into multiple filtration units, each equipped with a filtration element such as cloth or metal mesh to filter materials and form a filter cake. The filtrate is collected through outlets below the filtration elements and flows to the control head.

Control Head and Filter Cake Discharge Outlet

The control head, independent of the housing sections, is responsible for collecting and discharging filtrate, washing liquid, and filter cake. The filter cake discharge area is designed to be at atmospheric pressure, discharging the filter cake through backblow gas and a discharge scraper. Additionally, a cloth washing regeneration device is equipped to ensure the long-term use of the filter cloth.

Drive System

The drive system consists of a variable frequency motor, reducer, and couplings that control the rotational speed and working state of the drum, adapting to various production process needs.

The rotating drum filter operates through the continuous process of "slurry filtration-filter cake washing-filter cake dewatering-filter cake discharge." As the drum rotates, different processes are completed sequentially in their respective sections. This design ensures the continuity and stability of the production process. The positions of the compartments can be adjusted according to different process requirements, allowing for the flexible application of multiple processes in different zones.

High-Efficiency Continuous Operation

The rotary drum filter integrates high-efficiency filtration, washing, and dewatering functions. By simplifying the operation process and reducing energy consumption, it saves substantial resources compared to traditional filtration centrifuge equipment.

Multi-Process Application

With its independently zoned design, the rotary drum filter can flexibly meet complex process requirements of different industries, such as multiple washings in the cellulose industry and multi-solvent applications in pharmaceutical intermediates.

Simple Operation and Maintenance

The rotary drum filter operates with simple and intuitive controls. By adjusting the speed and material layer thickness, the process effects can be regulated. It requires minimal maintenance, saving on labor costs.

Safe and Environmentally Friendly

The fully enclosed design ensures safe and environmentally friendly operation without the need for additional explosion-proof facilities. It is suitable for long-term stable operation and industries with strict environmental requirements.

Durable and Reliable

With minimal wear parts and a carefully designed lubrication system, the equipment ensures long-term stable operation, significantly extending its service life.

The rotating drum filter, as a high-efficiency, multi-functional continuous filtration device, not only enhances production efficiency but also reduces production costs and environmental impact. It is widely used in various industrial fields globally.